A new 3D printing process can produce complex and highly porous glass objects, researchers report.

Producing glass objects using 3D printing is not easy. Only a few groups of researchers around the world have attempted to produce glass using additive methods.

Some researchers have made objects by printing molten glass, but the disadvantage is that this requires extremely high temperatures and heat-resistant equipment. Others have used powdered ceramic particles that they can print at room temperature and then sinter later to create glass; however, objects researchers produce in this way are not very complex.

The new method is based on stereolithography, one of the first 3D printing techniques developed during the 1980s. Researchers have developed a special resin that contains a plastic, and organic molecules to which glass precursors bond.

The researchers can process the resin using commercially available Digital Light Processing technology. This involves irradiating the resin with UV light patterns. Wherever the light strikes the resin, it hardens because the light sensitive components of the polymer resin cross link at the exposed points. The plastic monomers combine to form a labyrinth-like structure, creating the polymer. The ceramic-bearing molecules fill the interstices of this labyrinth.

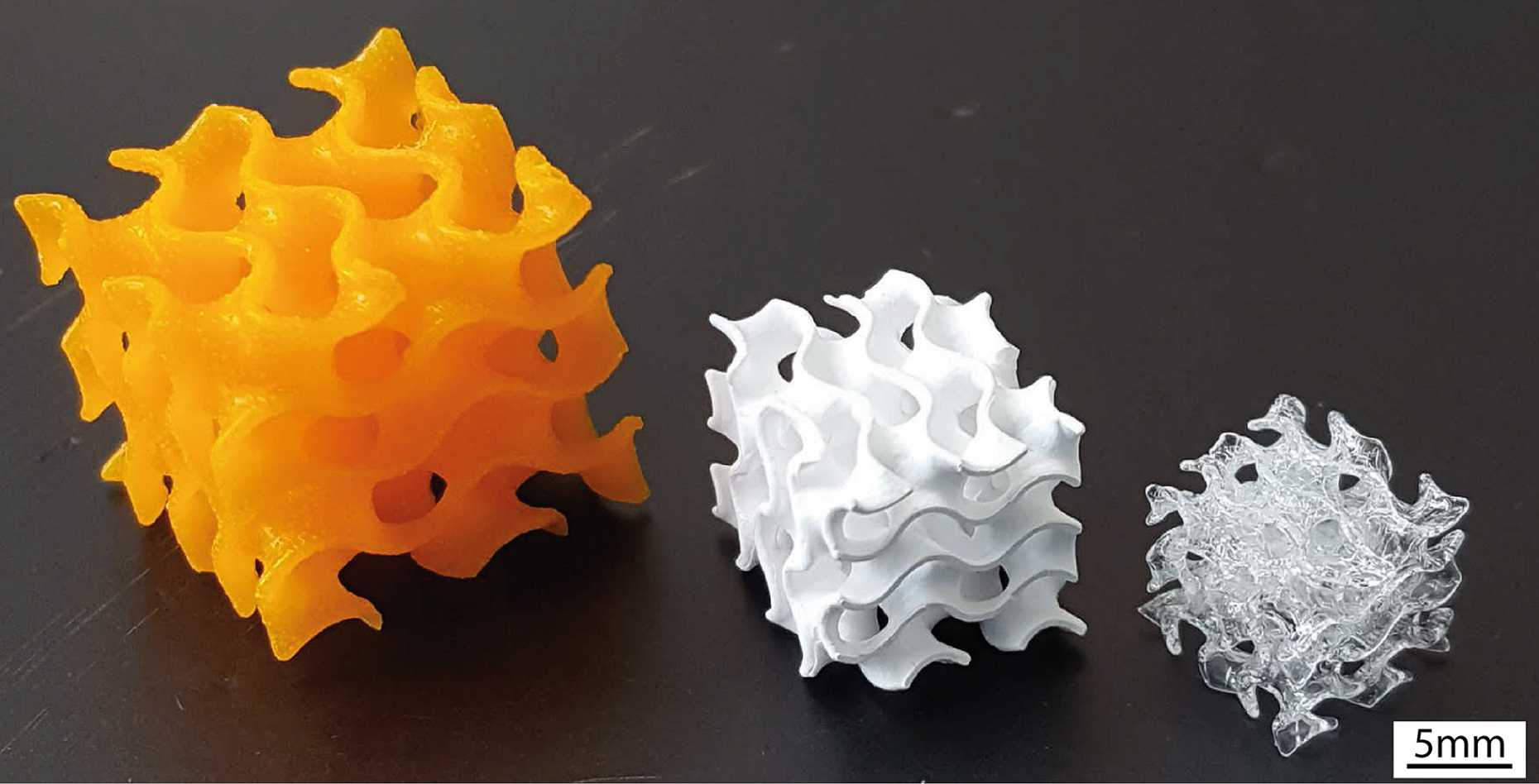

Researchers can use the technique to build an object up layer by layer. They can change various parameters in each layer, including pore size, too: weak light intensity results in large pores; intense illumination produces small pores.

“We discovered that by accident, but we can use this to directly influence the pore size of the printed object,” says Kunal Masania of the Complex Materials group at ETH Zurich.

The researchers are also able to modify the microstructure, layer by layer, by mixing silica with borate or phosphate and adding it to the resin. They can make complex objects from different types of glass, or even combine them in the same object using the technique.

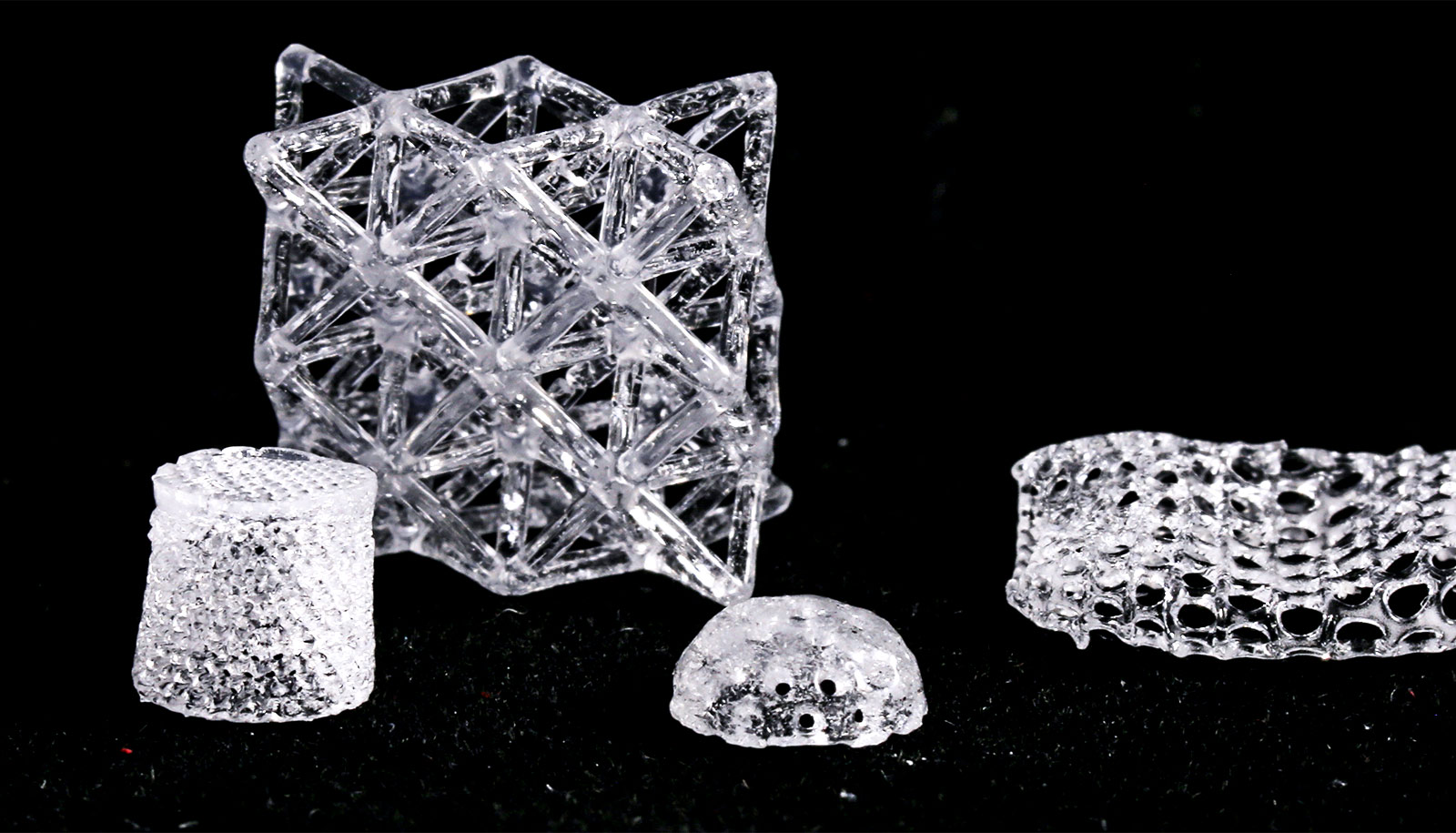

The researchers then fire the blank they produced at two different temperatures: at 600˚C to burn off the polymer framework and then at around 1,000˚C to densify the ceramic structure into glass. During the firing process, the objects shrink significantly, but become transparent and hard, like window glass.

The researchers aimed to prove the feasibility of producing glass objects of complex geometry using a 3D printing process. However, the new technology is not just a gimmick. The researchers applied for a patent and are currently negotiating with a major Swiss glassware dealer who wants to use the technology in his company.

The researchers reported their results in the journal Natural Materials.

Source: ETH Zurich